“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

Note: Working on high-voltage systems should only be performed by a trained professional. The Dorman Training Center offers automotive training programs tailored to your shop’s needs and taught by ASE-certified instructors. Learn more at: https://www.dormantrainingcenter.com/shop-training

There’s a whole list of shop procedures, tools, and personal protective equipment (PPE) necessary to work on automotive high-voltage systems safely. Chief among them are the Class 00 insulated gloves that keep you from getting a nasty shock. But don’t make the mistake of thinking you can treat them like any other work gloves. Here’s why you need to test your high-voltage work gloves before using them.

When working with high-voltage systems, it is imperative that you follow the manufacturer’s safety requirements. In most cases, that means you actually wear two pairs of gloves: an inner insulating pair (Class 00 made of rubber) and a protective outer pair (typically leather). The outer glove protects the inner glove from physical damage, and the inner glove protects you from being shocked. They must be worn together, as the inner gloves are not designed to handle physical damage, and the outer gloves are not meant to stop electrical current. And before you ask, welding gloves are not the same, nor will they protect you at these high voltages (but that is a common question).

Glove testing is important when servicing these. Photo: Brian Medford.

Most people working in a shop have been zapped by a 12-volt circuit. But the power stored in a modern hybrid or electrical drive battery can be hundreds of volts, and your body won’t like the amperages, either. At these power levels, a shock isn’t limited to severe injury; it can disfigure or kill. That’s why special insulated tools, safety gear, and procedures are necessary not just for your safety but also for the safety of the people in the shop around you.

Insulated gloves get damaged in a number of ways. Cuts, tears, and punctures can create a path for electricity to flow. All it takes is a tiny pinhole to get a bad shock. Over time, rubber begins to degrade, which can lead to cracking or splitting. Something as simple as not storing gloves correctly can also cause damage. That’s why testing is so important.

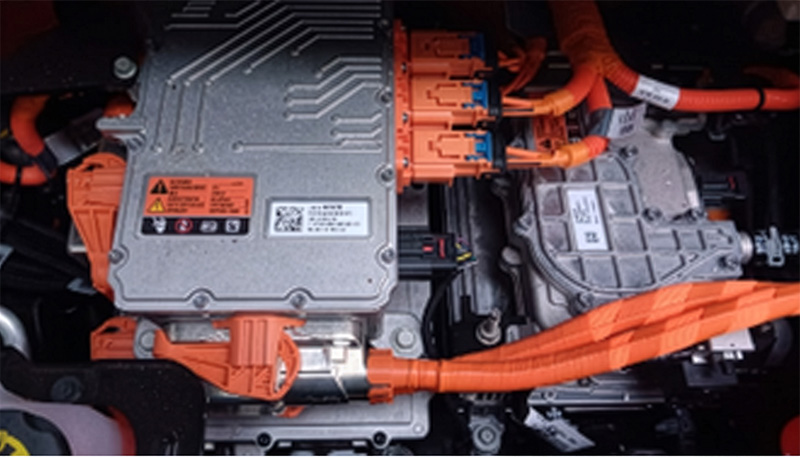

Hybrid battery. Photo: Mike Apice.

According to OSHA section 1910.137(c)(2)(ii), before starting a high-voltage work day, you must inspect your gloves for any tears, cuts, scratches, holes, or any other damages listed in OSHA section 1910.137(c)(2)(iii). The following information is an overview of the inspection procedure, but the full in-depth process can be found in the ASTM F1236-96(2012) Standard Guide for Visual Inspection of Electrical Protective Rubber Products. Of course, you should also always consult OEM manuals, conduct regular training, and perform risk assessments before starting any job in the shop.

For inner insulating gloves, start by rolling the cuff between your fingers while looking for any damage. Next, look at the palm and each finger, making sure to pull each finger apart to check the areas between where a split may hide. If the glove passes a visual inspection, it must also pass an inflation test. Tempted to use your mouth to blow into the glove? Don’t risk it. Moisture from your breath can affect the insulating capability. The preferred method is to use a special glove inflator that makes it easy to test the entire glove quickly. Another method taught to dealer technicians is to roll the cuff of the gloves up to push air into the palm and fingers. Now squeeze the inflated glove while listening and feeling for any air leaks. Find a leak? Toss them in the trash and get a new pair.

Outer gloves must be checked for anything that might allow the inner glove to be damaged. Cracks, tears, loose stitching, worn spots, or embedded dirt can all lead to inner glove damage. Make sure the outer glove is flexible but not cracked. It also needs to fit over the inner glove completely. When in doubt, replace them.

Hybrid battery and bus bar. Photo Mike Apice.

This step will be new to most shops. According to ASTM F496, your gloves must be tested and recertified every six months. You can ask your PPE supplier for a local test laboratory or visit the North American Independent Laboratories (NAIL) website for a list of testing facilities. If the gloves pass the test, they can be put back into service; otherwise, they must be thrown away. If the gloves have been stored longer than 12 months they must also be recertified or replaced, despite not being used.

Proper shop safety procedures must be a part of every job. When it comes to high-voltage system safety, there can be no shortcuts or skipped steps. Don’t forget to use an approved glove talc before putting the inner liners on. This is a cooling, frictionless powder that absorbs moisture and perspiration to cool and protect hands when wearing the high-voltage rubber gloves, not to be confused with your ordinary convenience store talcum powder. Electricity is very good at finding a way to complete a circuit, even if that path is through you. Make sure to add insulated glove testing to your own shop equipment maintenance schedule. Stay safe out there!

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.