Patching a punctured tire is a common job, but are you up to date on the latest guidance for safe plug locations?

A refractometer measures how light bends through a fluid. Remember when you put a pencil in water and it looked “broken” as a kid? As it turns out, a bunch of smart folks a long time ago realized that the angle of the pencil’s break is related to the density of the fluid. In the automotive world, we can use that information to determine a given fluid’s concentration. The refractometer has a plate where a fluid can be deposited that allows light to pass through the liquid and a prism that has known characteristics.

Coupling the output of a given fluid with an appropriate scale, we in the service bay can determine the concentration of quite a few fluids—a very handy ability.

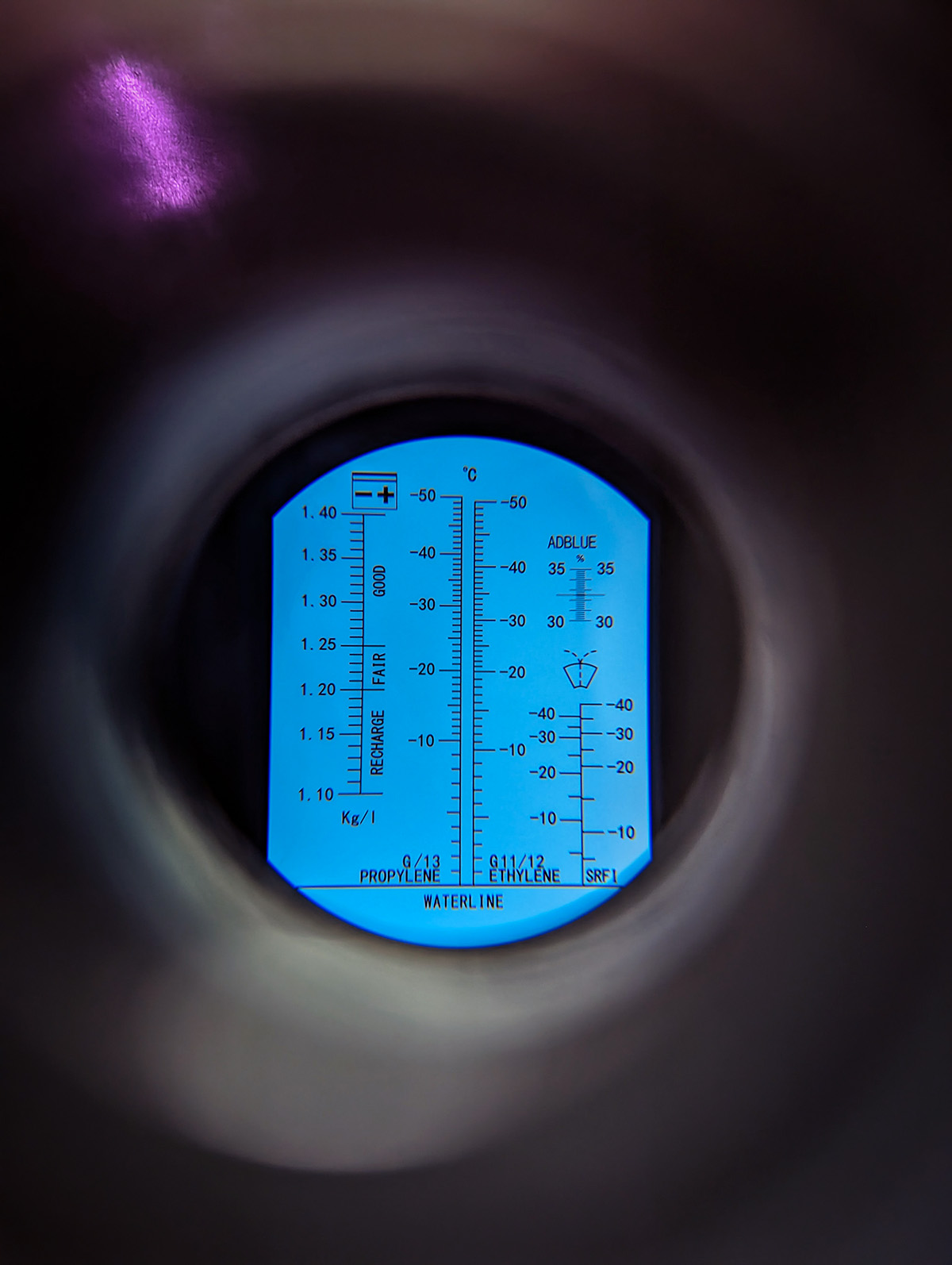

At the time of this writing, auto-specific refractometers can be had very inexpensively—$25 is about the going rate. You should know refractometers are used in determining the sugar concentration of jams and jellies, to determine the alcohol level (ABV) of wines and beers, and by apiarists to determine the moisture content of honey. All use different scales, so it’s important to look for an auto-specific model. Some will be calibrated for just one or two fluids, but it’s possible to obtain one with a series of carefully arranged scales like you can see in the image below. This arrangement allows a tech to test the concentration of battery acid, both types of coolant, DEF, and washer fluid—not shabby.

Refractometers are no different than many other tools that are designed to measure—they need to be calibrated. The first thing you’ll want to do is calibrate yours. This is easy to do, but there’s one annoying part: you’ll want distilled water to do it. Since the tool effectively measures solids within a fluid, “water” isn’t specific enough to calibrate. Pure, distilled water will give you a perfect baseline.

Flip open the protective door and get some water on the plate underneath, known as a daylight plate. You can use a pipette or even just something you dip into the fluid you’re testing and dribble some on there. A few drops is all it takes.

Moving that screw will raise and lower the scale to match the pure water’s line. Photo: Lemmy.

Bring the eyepiece up to your eye and point the unit at a light source. You should see the water’s line hopefully somewhere near (you guessed it!) the water line. If it’s not precisely aligned, pop off the protective cap to access the adjustment screw shown and twist it until it’s dead-on. Then you’re done calibrating.

Using it to test a fluid is no different, only the fluid line will be much closer to the top of the scale. All you need to do is match the level with the scale for the fluid you’re testing.

To be clear, the “floaty balls in the turkey baster” work just fine. I do think it can be easier with the refractometer to obtain a fluid sample, especially in some of the convoluted fluid reservoirs that exist today. Even a little piece of mechanic’s wire bent just right can fish out the few drops of fluid you need.

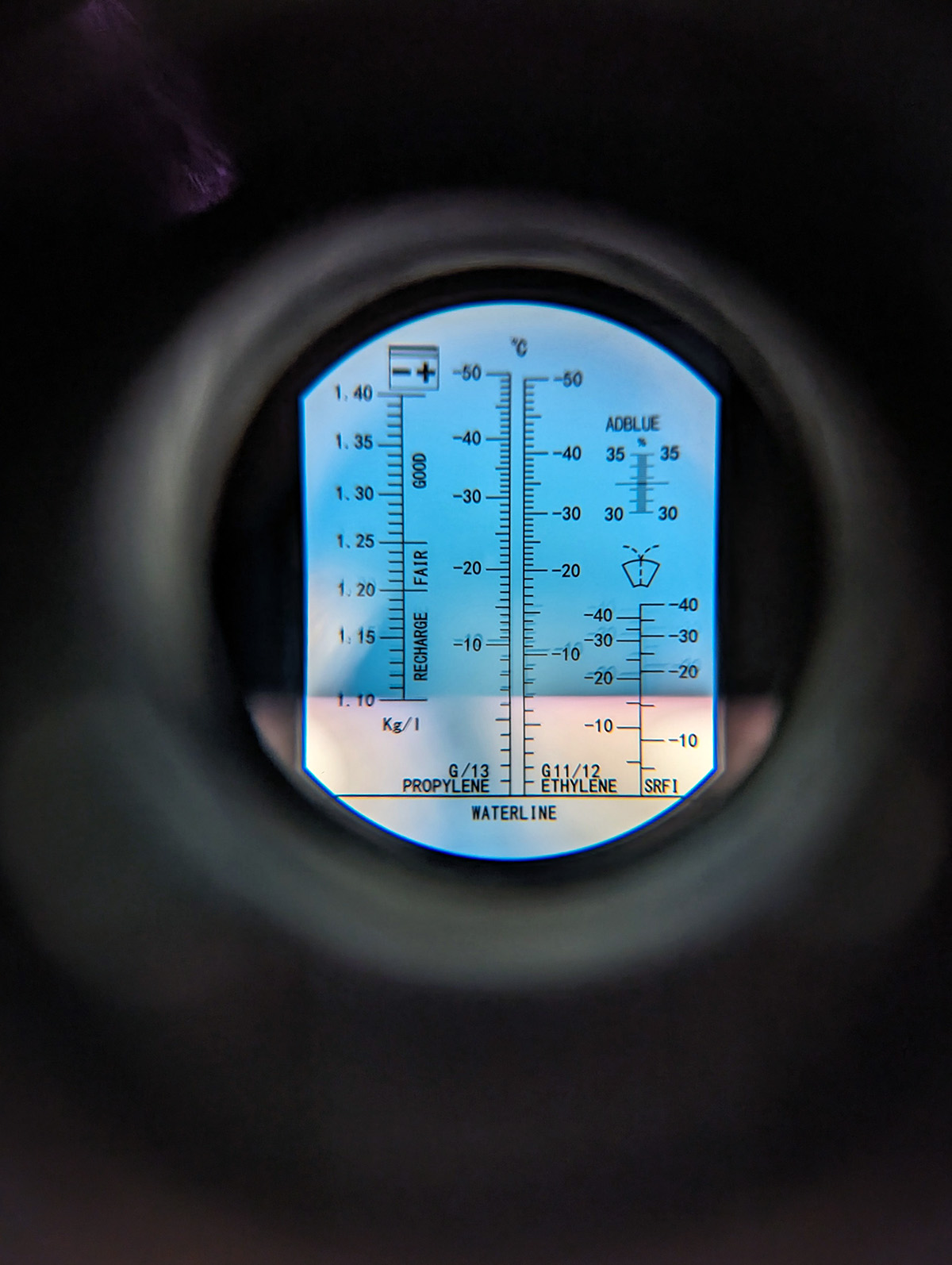

The bigger item to me is that it’s easy enough to snap a photo of the test results for your customer (and for your own records lest needed service be declined).

A little cropping and this could be sent to a customer as polished-appearing evidence that a fluid change might be in order, especially coupled with a pH test (if relevant for the fluid). Photo: Lemmy.

I think even my quick cell phone snaps here look a little more professional and are easier for a customer to interpret than an image of some floating balls with a messy background.

In summary, this is a neat tool and I’m stoked Pete turned me on to it. Try one out and see what you think!

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.