Don’t leave alternative vehicles on the sidelines.

My wife and I are RVers and started our RV adventure with a 23’ toy hauler. When we started, we pulled the trailer with a Ram 1500 equipped with the 5.7-liter Hemi engine, and for most outings, it handled the task just fine. It wasn’t until we took a trip to the North Carolina mountains that I realized my Ram just wasn’t up to the work I was asking it to do. Considering, too, the known Hemi weakness of wiped lifters and cam lobes, I began to rethink my choice of tow vehicle.

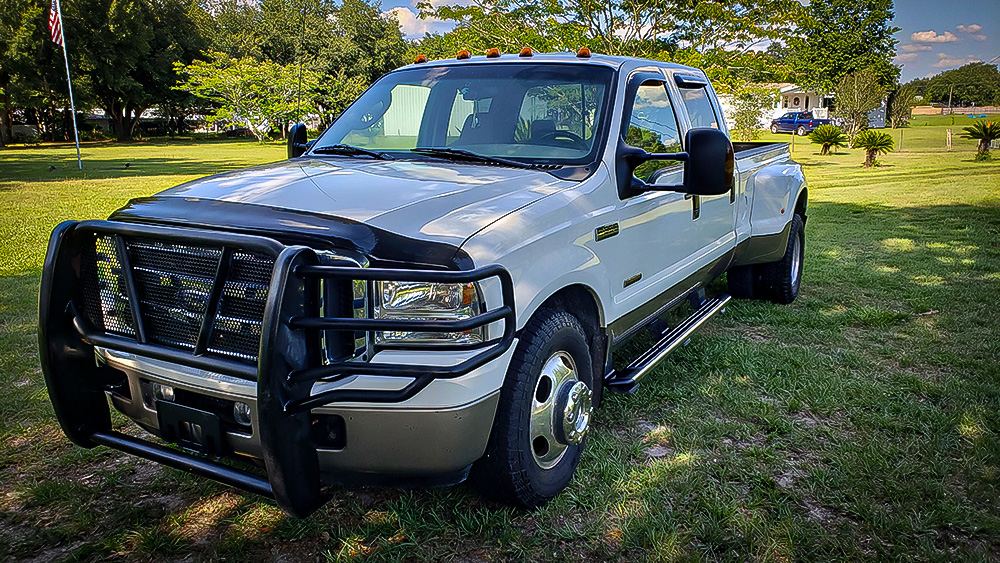

By chance, my son had a truck he wanted to sell. It was a 2005 Ford F-350 dually equipped with the 6.0-liter PowerStroke diesel. Considering the capabilities of this truck, I was pretty sure it would tow my little rig without breaking a sweat and would leave the door open to any future trailer upgrades my wife and I might consider.

Did I make a horrible mistake?

At the time, I had very little experience working on diesels, but I quickly learned that the 6.0 seemed to have more than its fair share of problems. But I reasoned that the truck had only a little more than 100,000 miles on the odometer, and I knew diesels were known for long lifespans when properly maintained. Given the few miles I put on a vehicle each year, I thought this truck would last me well into my retirement.

One morning, after I had owned the truck for well over a year, I went to start it and nothing happened. Reviewing what I had learned from reading all those diesel articles, I quickly identified the fault as a failed Fuel Injection Control Module (FICM). This is one of the common failures on this model truck.

While I was reading up on the proper way to diagnose a 6.0 with a “no start” condition, and becoming more familiar with the nuances between a diesel equipped with HEUI (Hydraulically actuated Electronic Unit Injection) and the gas powerplants I was comfortable with, I happened across numerous articles related to the pattern failures associated with it. But I also found more than one article that touted the engine’s capabilities despite its faults. After all, at its initial release, it was considered the new benchmark for diesel engines, delivering the highest horsepower and torque in its class, with an impressive 325 HP and 560 lbs-ft of torque.

I also learned a new term: “bulletproofing”.

Adding a turbo and new injectors, as well as a return fuel system and pressure regulator. Photo: Pete Meier.

There are arguably four or five areas on the 6.0 that are the most likely to fail. One is a failure that I have already experienced: the FICM.

But the FICM isn’t Number One on the Hit Parade. At the top of the list are head gasket failures caused, due in part to the Torque To Yield (TTY) bolts Ford used. TTY bolts are designed to stretch when tightened must be replaced every time one is removed. In the 6.0’s case, higher-than-normal pressures in the combustion chamber can cause these bolts to stretch further, leading to cylinder head lift and eventual head gasket failure.

Many 6.0 owners with high-mileage engines have never experienced this failure. And a big reason, it seems, is that they maintain their trucks and are plenty satisfied with the power they make in stock form. It appears that most who suffer from head gasket failures have aftermarket tuners that allow them to alter the Engine Control Module’s programming in pursuit of more power. The F-350 I own came with a tuner, and my son, after the sale was completed, was quick to share that he could smoke the rear tires off the truck with the most aggressive tune selected.

Another common problem is the EGR cooler failing, which is reportedly rarely due to an issue with the cooler itself. The real culprit, it seems, lies in the coolant’s contaminants. The coolant passages in the oil cooler gradually narrow, reducing coolant flow to the EGR cooler. Depending on the source, the cause of the restriction is either sand remaining from the casting process during manufacture or the drop-out of silica from the OE coolant formulation. When it fails, one of two things will happen. One, the cooler leaks a little coolant into the intake manifold, and it passes out of the vehicle’s exhaust or two, exhaust back pressure (which can run anywhere from 10 psi to 50 psi), finds a break in the cooler, and enters the coolant passages, which can lead to a variety of issues, including head gasket failure or potential hydro-lock.

Next is the oil cooler itself. It is internal to the engine, and oil passes through it before it returns to the oil filter. This allows contaminants in the oil to build up in these passages, leading to restricted oil flow.

An arguable fifth failure is the factory water pump. One way to gauge the health of the coolant flow is to monitor the engine oil and coolant temperatures. The factory specification requires that the two never be more than 15°F apart. Anything more than that indicates an impending problem.

If you are looking for a diesel truck, a new one will cost $60k to $100k. But used 6.0 F-250s or F-350s with 150,000 to 200,000 miles on the odometer are out there for $8k to $14k. Depending on how much work you can do yourself, you can address these pattern failures starting at $3,000 for parts alone or up to $20,000 for a professional bulletproofing makeover. Add in the fact that 6.0s that are already bulletproofed can sell for upwards of $40,000 and you could come out ahead. Considering how much a new or late-model truck costs, this could be a real value.

One look under the hood now, and you’ll know this truck is no longer stock—It’s bulletproofed. Photo: Pete Meier.

Here’s what I did to mine:

While I was at it, I also replaced the fuel injectors and turbocharger, opting for a design like the turbos used on the older 6.0s. I must admit that I’ve come to love the sound of the old diesels, and it’s that jet engine whine I love to hear as the turbo spools up. I also replaced the boots on the charge air cooler pipes and found a downstream pipe that includes a mounting point at the alternator bracket. This helps prevent the pipe from blowing off under high boost pressures, another common issue with 6.0s when the boots age or become contaminated with oil.

My experience with this truck quickly introduced me to the way of the diesel powerplant, and the lessons I learned have served me well when challenged by other diesel makes and models. If you can learn your way around the venerable 6.0 Ford, you can learn your way around any current diesel offering the OEMs offer.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.