“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

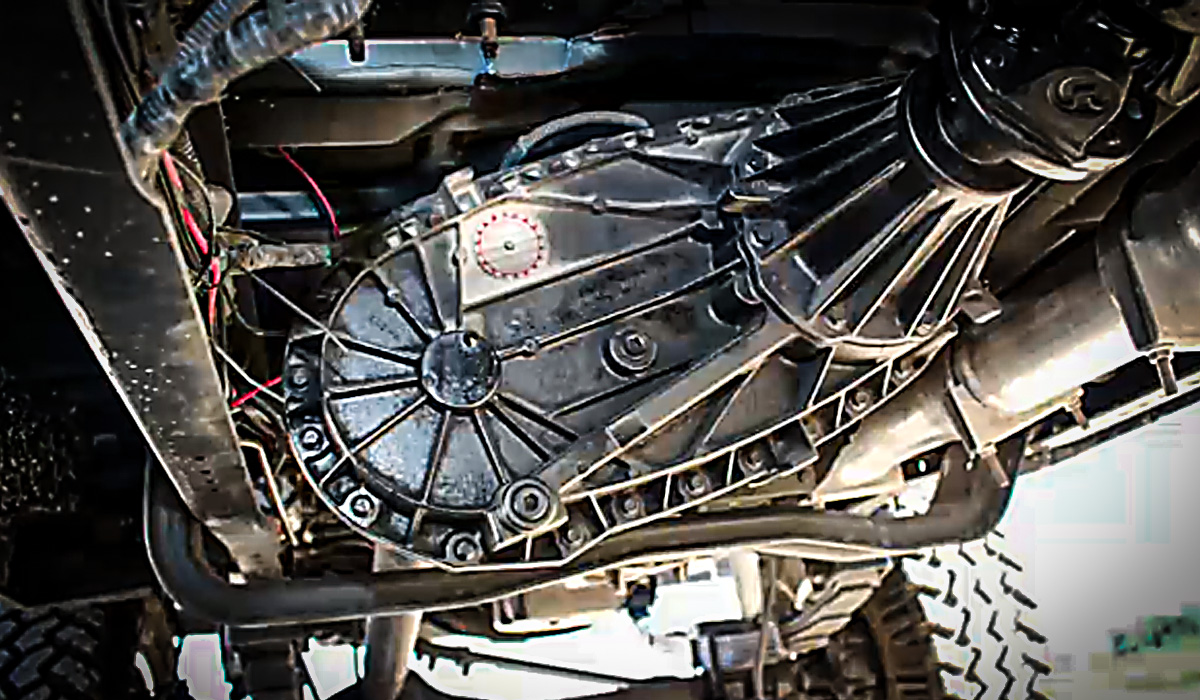

Other than what Andy mentioned, like seeing what the T-case is bolted to? Just count the yokes or shafts attached to the unit. If you see two (one output heading to the front axle and one output to the rear axle), it’s a married case. Three yokes (one input, the rear output, and a front output) is found on divorced arrangements.

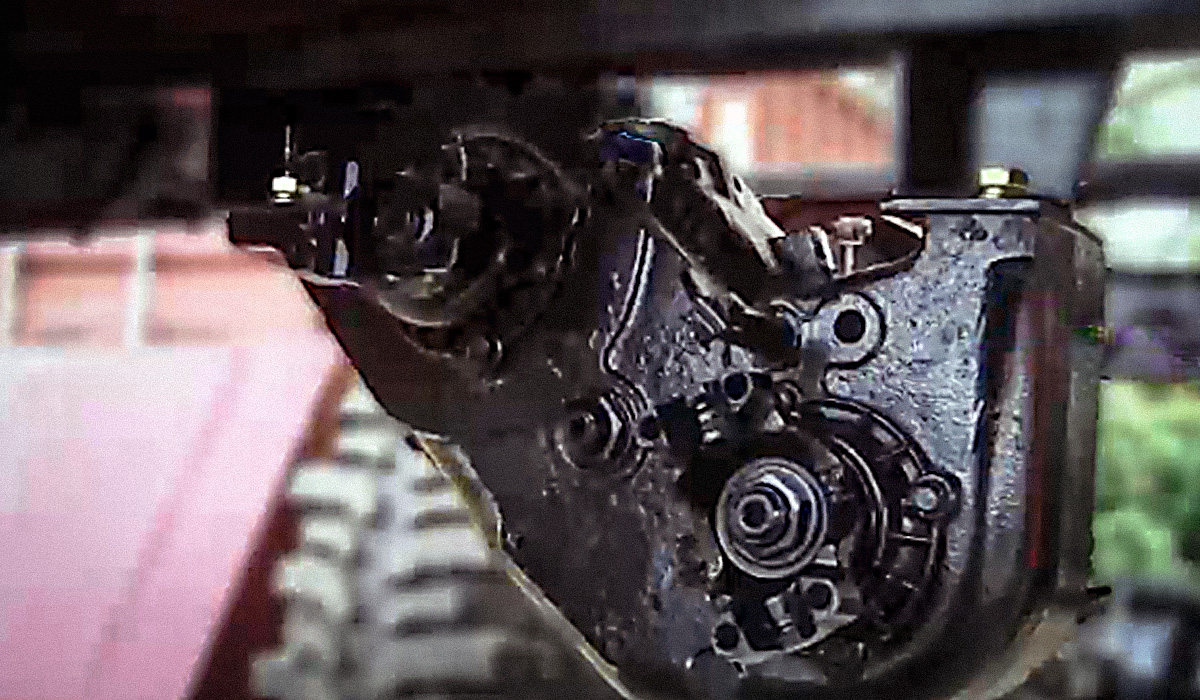

Way back when, RWD was the dominant form of drive. When 4WD came into vogue, it needed to be a separate system that was grafted on, so a divorced transfer case was almost the only way to make that work. Engineers figured out that they could reap a few benefits with a married design: stiffer construction, a reduction in parts (the associated driveshaft, yokes, and U-joints) all while eliminating potential leak locations. However, there was an obstacle to this: the transmission had to be designed for such a thing. An early 2WD transmission was never created with the notion of bolting another heavy gearcase to the back of it.

As vehicle designers began to account for the possibility of offering 4WD, transmissions were designed with tail shaft housings that could be swapped out to accommodate transfer cases for vehicles with a 4WD option.

That is confusing, isn’t it? I think some of that lore has to do with two other aspects of the case. Given that divorced cases from way back when didn’t have the stiffening aspect of being bolted to a larger unit (the trans), they were often made from cast iron due to the metallurgy of the day.

Today, that means cast iron T-cases may be seen as a little tougher in an offroad scenario because rock strikes and debris impact that would window an aluminum unit might have no apparent effect on the iron case. Aluminum is of course lighter and also dissipates heat a bit better.

The second aspect is the bits inside. Most modern, married t-cases are driven by sprockets and chains since noise and weight are greater considerations today than they were many moons ago. Way back when, some t-cases were driven gear-to-gear. Those babies are often tolerant of abuse.

In any case (I’ll show myself the door, thank you), there are certainly very rugged examples of each design.

Andy mentioned custom 4WD rigs; why exactly do they want divorced units?

Well, two reasons. One is flexibility. Off road, short wheelbases and high ground clearance can make for a more useful trail truck. But those very same characteristics can make for some really weird driveshaft angles and can make for shafts that wind up hanging too low.

So there you have it. The divorced T-case ain’t dead yet—but don’t expect to see a ton of them.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.