“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

As a new tech, all I did was borrow tools from mechanics who were good to me. They usually lent and trained me on etiquette just after. (If you need to borrow it more than once or twice, maybe you ought to buy your own.) It’s not that often that I find myself without a tool these days in part due to having most of what I need and also in part to not being so pressed for money. But recently I found myself under a car needing something I didn’t have, so I thought I’d send out a little PSA for those of you who could end up in the same boat.

I was about to perform a service that doesn’t come up very often: a manual transmission fluid exchange. I’ve written before about my good friend the drain plug, so this was an interesting development: I had some trouble removing one recently, but that was no fault of the plug. Here’s what transpired on the Nissan that found its way onto my lift.

I can’t speak for you, but I personally always crack fill plugs before drain plugs. The fill plug was a little plastic butterfly affair. Easy-peasy; I spun that out and it was no problem.

Hmm. Not as straightforward as I thought. Photo: Lemmy.

Moving along, I readied the drain pan and spied what I thought was your standard 3/8” square drive slot broached into the plugs. I waltzed over to my box, grabbed a 6” extension, and when I inserted it, it was not fitting. No go. Maybe it was 1/4”?

Nope. Way sloppy.

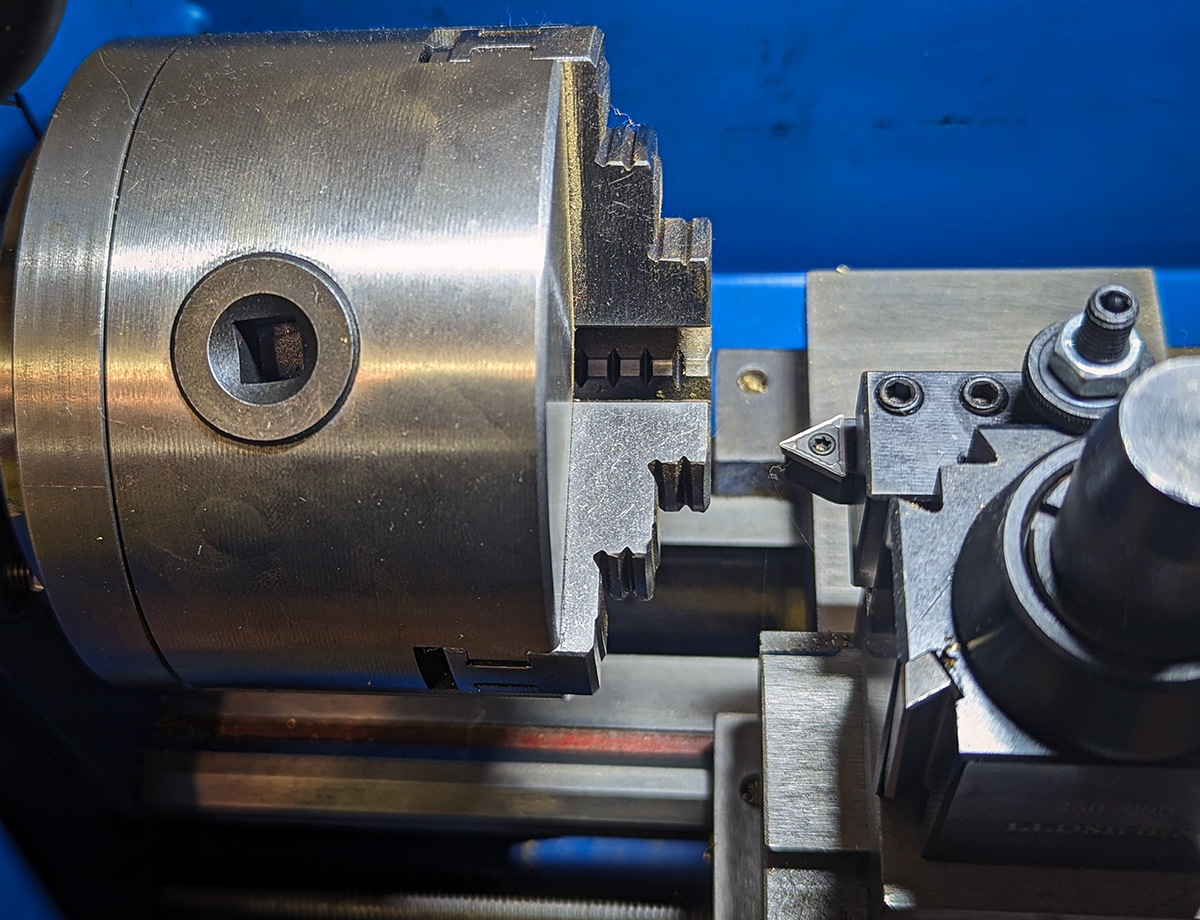

I thought I knew what was going on, so I walked over to my lathe, which is imported, and grabbed the chuck key, an 8mm. I’ve only ever seen metric square stuff on Asian three- and four-jaw lathe chucks, but happily I had a tool on-hand to deal with them thanks to that. I popped it in, and bingo! That was it. I proceeded with the service uneventfully.

An unlikely solution to my problem was fortunately close by. Photo: Lemmy.

So today’s PSA is to grab (or make) yourself some tools to deal with these little things. Order some square stock, file down some junker hex keys or grab a set of sockets. I bought a set for my drawer; it was oddly cheaper than buying the stock to make my own.

This 8mm was on a Nissan, but Suzuki uses this style of plug on their cars and light trucks, too. Engines, trannies, and diffs all might have similar plugs on BMWs, Fords, Renault products, and Toyotas. (This depends on the vehicle model and market.) Through the grapevine I’ve also heard lots of domestic T-cases make use of this plug, too.

Ordinarily, I’m not a tool junkie. But fluid exchange happens a lot. I’m certain I’ll get my money out of these sooner rather than later. Photo: Lemmy.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.