“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

I’m going to share some theory behind bypassing air conditioning in this article. I recognize it may be elementary for some of you (who probably lived through the whole history I’m gonna delve into), but it may be quite the revelation for those who have not. In most scenarios, customers simply want an HVAC system that works correctly, and you probably hook up your recovery machine and get to work. But that can get spendy quick.

Enter the A/C bypass pulley, designed for this specific breed of customer: someone who needs a compressor repair so the vehicle functions, but can’t or won’t spend the money on one.

This history lesson will help techs know how and when to use these parts, but it can also be of value to shop foremen and writers trying to accurately estimate the cost of a repair AND see what options exist, since a lot of this research can be done from a desk.

Understanding some of the history of a/c implementation in vehicles helps you understand just when it’s appropriate to recommend one to your customers. There’s a chronological history of how mechanics have dealt with a compressor that’s going to be removed from the accessory drive system, and the solution has gotten more complex as vehicles have, as well. Knowing the history helps you write the cheapest estimate for the customer in the least amount of time.

Dorman sells A/C bypass pulleys, of course, but you might not need one. My education on these began when I was selling them across a counter. I started slinging parts as a counterman in 2002, and by the time a vehicle is old enough that it has an owner who makes his own repairs and shopping at an auto parts store, it’s at least ten years old and often much older, so I got to see a fair cross-section of vehicles of varying age.

A word of caution, though, first. The A/C system is often used even in the winter to prevent fogging in Defrost mode by dehumidifying the air. It can be an integral part of the high voltage battery and component cooling system on hybrids and EVs.

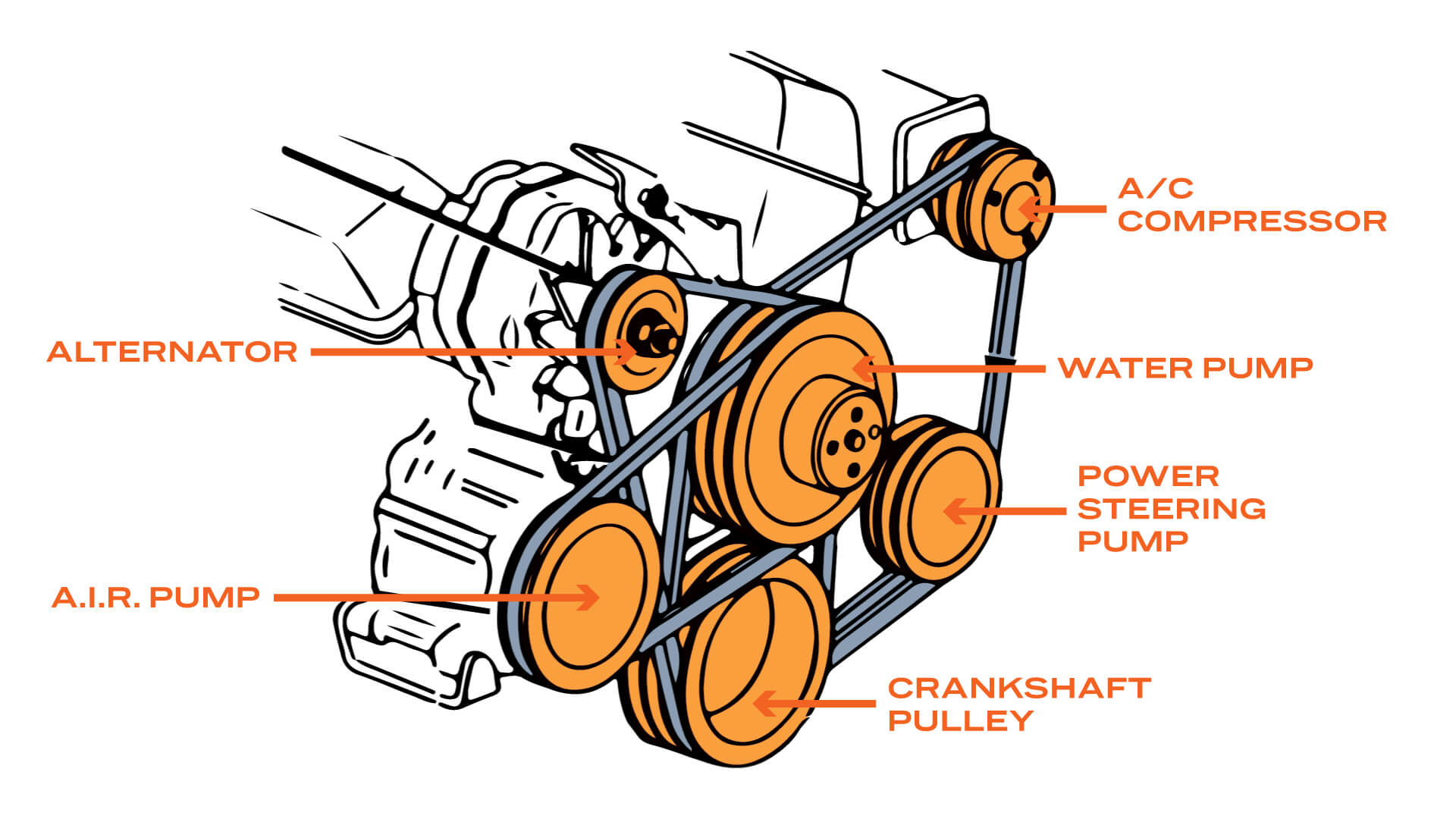

Early on the counter, I learned people with older vehicles or pickups could simply cut or remove the A/C belt on a vehicle using V-belts for the accessory drive, and then the compressor wouldn’t spin. Easy peasy and basically free in terms of parts and labor. Cut off the belt, and now the other accessories on other belts spin, and the compressor just sits there like the proverbial bump on the log. Heck, if the customer could deal with the belt noise and smell that a locked-up compressor could generate, the belt would eventually just fall of on its own.

A/C compressors hailing from the days of V-belts can be isolated from the accessory drive with ease. Illustration by Josh Seasholtz.

You won’t see many of these drive systems any more, but sometimes an A/C belt is run off a separate drive circuit. The design persisted because the added expense of things like power steering and air conditioning meant a modular system made sense. Since air conditioning was a high-end option in this time period, the compressor was almost never integral to the system; it drove nothing else. Instead, another driven item would be given another row on its pulley, and that item would then drive the compressor. This same idea is prevalent in older Japanese vehicles that utilize narrow-diameter flat ribbed belts with multiple rows, really not unlike older domestic V-belt arrangements.

This idea carried over into the next iteration of accessory drives.

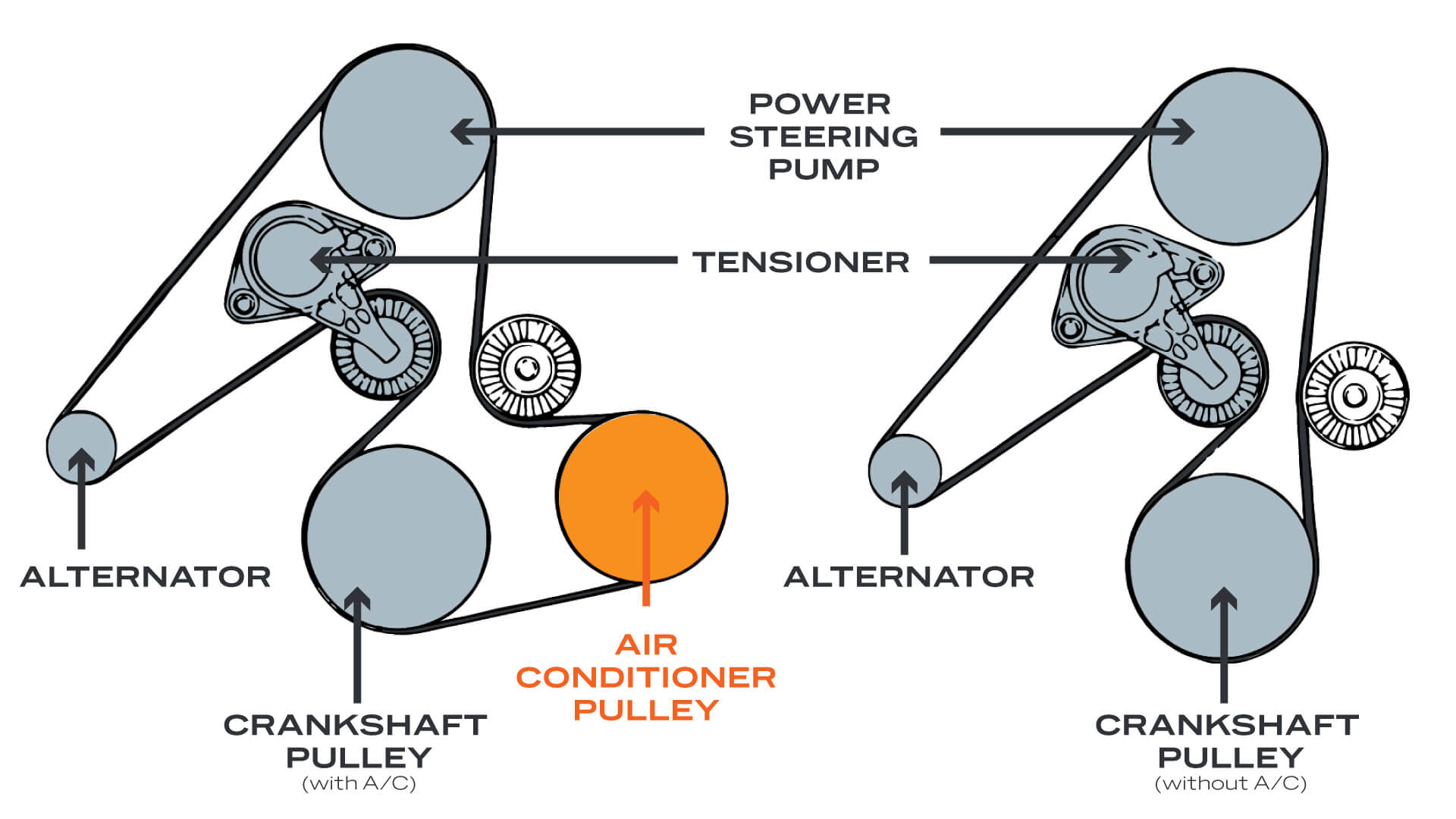

Chronologically, one then began to see serp belt drive systems developed for vehicles that still had optional air conditioning. Because these cars may or may not have been sold with a compressor, it was almost always placed in such a spot where a shorter belt (for the non-A/C-equipped cars) could be put into play. Translation: on a car with a bum compressor, you could run the shorter belt and leave the compressor to just sit there unused.

Some systems feature a design such that a shorter belt is all that is required to remove the compressor from the system. Illustration by Josh Seasholtz.

If a counterman or tech knew a car was sold without air, you could just order the belt for a non-A/C car and be off to the races. (A quick cheat code for this was to look up a serp belt and see if a shorter, non-A/C belt was cataloged.)

It bears mention that there are vehicles out there that were never sold without air, but still maintain this design. (Often this was carryover on older engines that might have been once been designed years earlier for a V-belt drive system powering non-air vehicles. Others were likely the work of a guerilla engineer lurking at an OEM. Others yet were probably just happy kismet.)

Due to extreme pulley sizes, crazy variations in routing, insane packaging constraints, and the diminishing lack of demand for easily bypassed serpentine routing schemes, we arrive at our present time, which is one where the compressor is more or less integral to the accessory drive system. (Seriously, when was the last time you saw a car sold without standard A/C? It’s even part of the heater on most modern cars—and even some not-so-modern ones.)

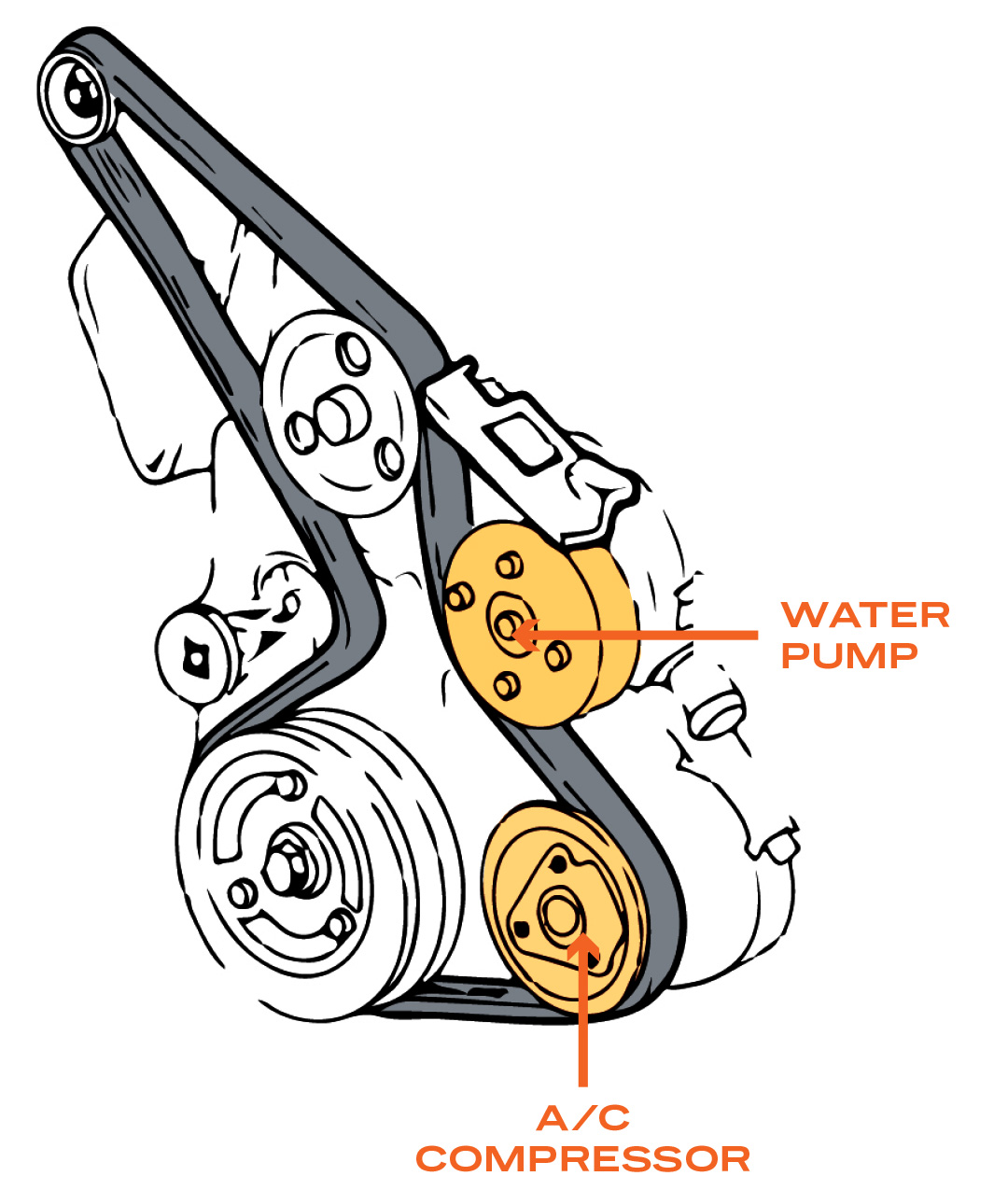

The long and short of it is that due to belt angles when pulleys are removed, reversal of direction of drive, and lack of clearance for longer straight runs of belt, removing the compressor is simply not possible in many current drive belt systems. If you want to remove it, you need to replace it with another spinning item to keep the rest of the system operating happily.

In this setup, if the compressor was to be isolated, the water pump would not rotate. Even if the pulley were switched to a grooved pulley to allow the belt to drive it, the rotation of the pump’s impeller would be incorrect. Illustration by Josh Seasholtz.

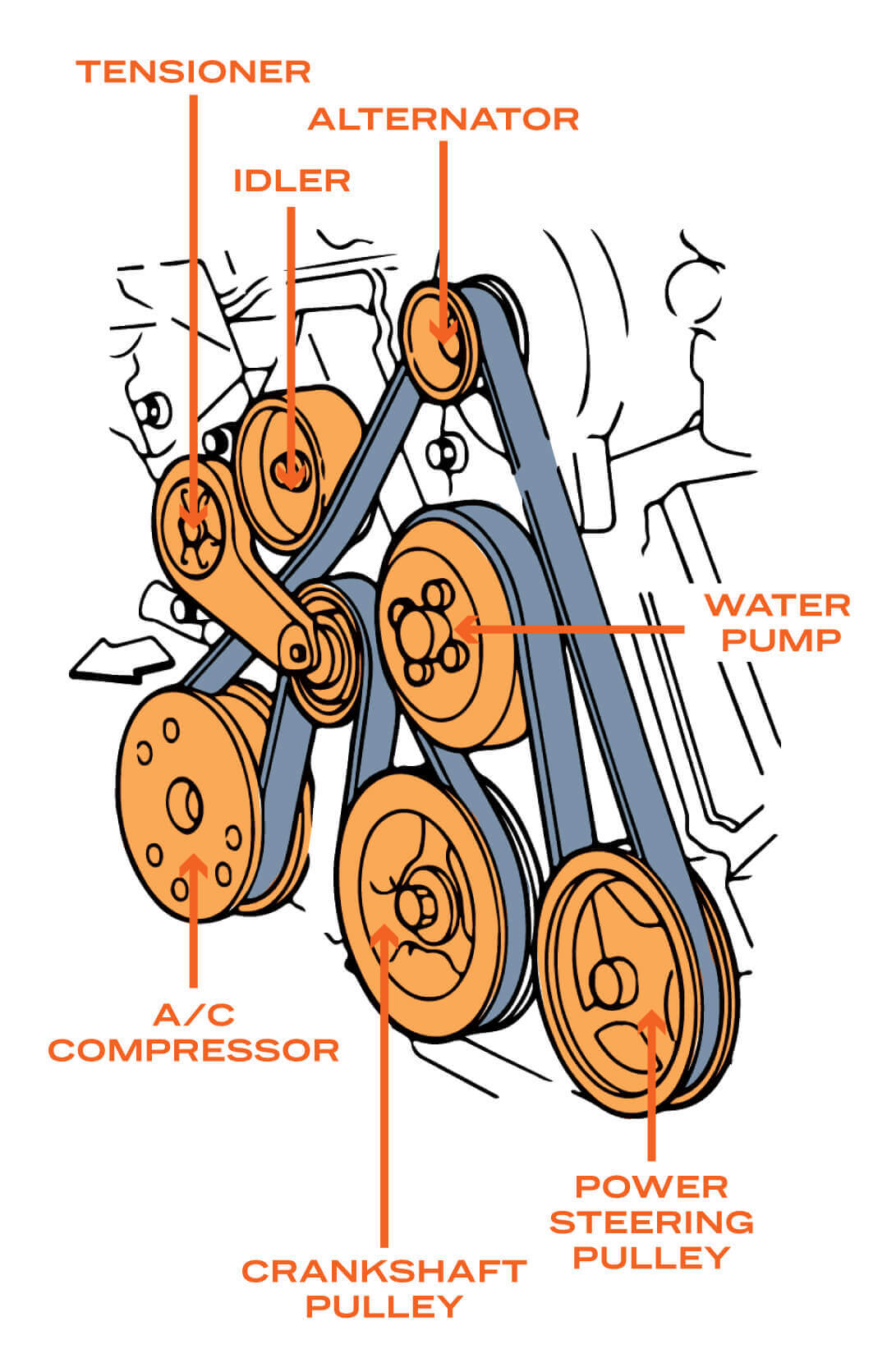

You can engineer your own solutions, too, of course. Let’s use a Ford 5.4L engine as an example. Taking one look at the routing diagram tells you the problem with trying to just eliminate the compressor: the idler is going to be running on the wrong side of the belt. That’s just the sort of setup we look for when identifying drive arrangements where techs would benefit from having a ready-to-install solution to save a price-conscious consumer a few bucks.

But what if you wanted to go a different route?

Idlers, as their name suggests, are just along for the ride. They siphon off very little power from the drive system, and usually exist specifically to change the power flow’s direction. Normally tensioners are smooth since they apply power to the back of the belt to tension it, but idlers can be grooved or smooth depending on what side of the belt they work on to redirect the power.

Unlike the previous example, the layout of this system can utilize the idler with a pulley swap since the change in direction of rotation won’t affect system operation. Illustration by Josh Seasholtz.

In the case of this particular Ford setup, it would be feasible to measure the diameter of the idler pulley and attempt to find another in a similar width, diameter, and rib count—only grooved. Then, the compressor could be isolated from the drive system and the belt re-routed in a new way that would keep everything running as designed sans compressor.

Of course, after you got that pulley, you’d need to have the guy in the bay next to yours help out and hold the belt tensioner in the middle of its travel. That frees you up to run a piece of string around the pulleys to get a measurement of the belt’s new length so the correct fit can be ordered.

The other downside is that the customer’s belt would no longer use the correct OE number, and the routing diagram under the hood becomes wrong, too, which could slow down a tech in the future. These obstacles aren’t insurmountable, but they’re enough that we think our A/C bypass pulley, 34191, might save enough headaches to warrant its modest cost.

There you have it, the condensed history of the accessory drive belt in America in automobiles and how it affects the mechanics who re-engineer things to keep vehicles on the road more affordably than the factories ever intended.

More importantly, it’s also the story of why you can’t find a bypass pulley for every car and why you probably don’t even want one in many cases. Dorman would certainly like you to buy our bypass pulleys—but only when you actually need one.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.