“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

Well, this was a humdinger. Let me explain how I ended up here.

Class 0.25 towing capacity, maybe? Photo by Lemmy.

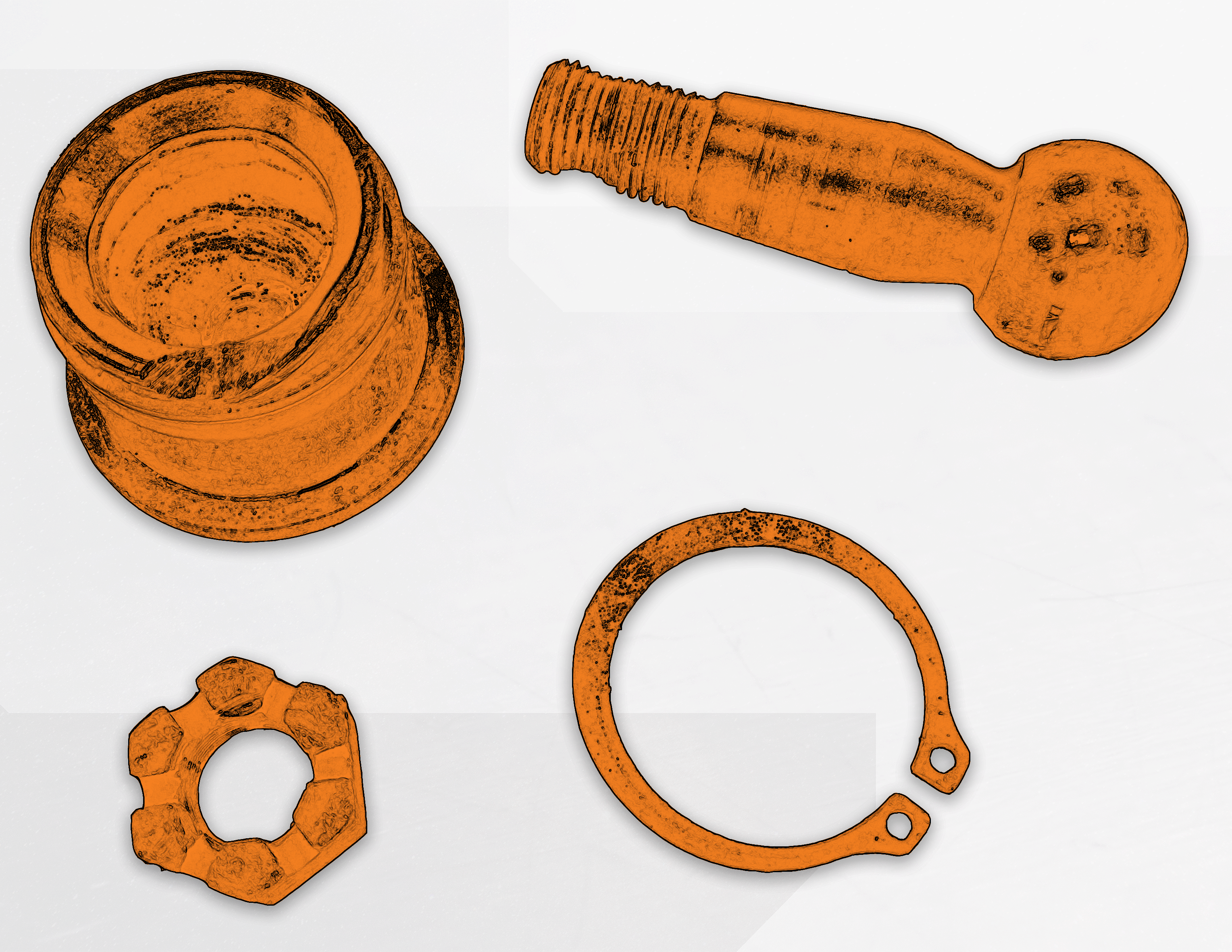

I was popping ball joints free from the lower A-arms so I could swing the CV axles out and replace the hub assemblies on this car. The left side freed up with a few taps. This side? Well, this picture is after the hammer, then the torch, then the big hammer and the pickle fork. Finally I separated the control arm from the knuckle using a homebrewed tool.

This wasn’t the way I was expecting to do it, though. As you can see, the ball stud actually fractured the socket, releasing it. This resulted in the ball joint breaking, rather than the stud end coming free of the lower A-arm and being able to be put back into service. At least in this position I was able to put the ball joint press on it, but it still had some fight left in it. After turning the press’ hex with The Persuader (my four-foot breaker bar) with a three-foot pipe over the handle, it cut loose.

Well, this is gonna be a fun job, I can tell right now. Image by Kyla Smith-Campbell.

And yes, for all you smartypants folks who will ask, yes, I certainly did remember to take the nut off before I started! On the bright side of the job, the bearings fell right out with very little fanfare, so at least I had that going for me.

Have a good Monday! I hope the rest of the week doesn’t go like this.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.