“Drive it ‘til the wheels fall off” isn’t the safest decision. So when does it end?

By some estimations, steel wheels should have faded into obscurity about two decades ago. That’s based solely on my highly unscientific and not-at-all-researched memory of when the used hub cap shop in Downers Grove, Illinois, closed its doors for good. Nothing left to sell, and no one left to sell to, presumably.

As the twentieth century faded into history, alloy wheels—once a pricey option reserved for high-performance and luxury cars—had become as common as fuel injection (itself a differentiator at one time). Steel wheels with plastic or metal covers looked decidedly down- market as overall equipment levels were rising across the automotive industry. If you wanted to see a steel wheel in the 21st century, your best bet was to rent a compact sedan. That’s how uncool they’d become.

Yet somehow, like cockroaches, GM 3800 V6s, and Converse Chuck Taylors, it seems steel wheels refuse to just die. In fact, they’re making a comeback of sorts—especially naked, sans cover—on some of the coolest vehicles in dealerships today. But how did that happen?

First, let’s take a quick look at the history of the wheel. We’ll skip the first few thousand years and fast-forward right to the automotive wheel, which in its earliest form evolved out of those used on primitive bikes and old-fashioned wagons.

Photo: iStock.com/Sjoerd van der Wal

The 1885 Benz Patent Motorwagen is widely recognized as the first modern motorcar. Driven by a rear-mounted single-cylinder gasoline engine, it delivered 2/3 horsepower to its two rear wheels. These, along with its single front wheel, were steel-spoked bicycle wheels wrapped in solid rubber. Given the modest power output of the 954cc four-stroke engine, this design was light and provided a measure of shock absorption, if not longevity.

As Carl Benz promoted his marvelous invention, he found the wheels no match for the rudimentary roads of the time, including brick-paved city streets. By 1888, the third version of the Benz Motorwagen was improved for long-distance touring (a record-setting 66-mile journey in August of that year by Mrs. Bertha Benz) wearing wood-spoked wagon wheels for improved durability.

For the next couple decades, these artillery-style wooden wheels would be the industry standard as motorcars gained popularity. Once Henry Ford and his moving assembly line helped put millions of Model Ts in America’s driveways, improving public roads became a national priority. With muddy ruts eventually becoming paved highways, rugged wagon wheels were no longer required to withstand harsh conditions in most urban settings. Shortly after the turn of the century, more robust automotive-grade wire wheels emerged as an alternative and would carry most vehicles through the 1930s.

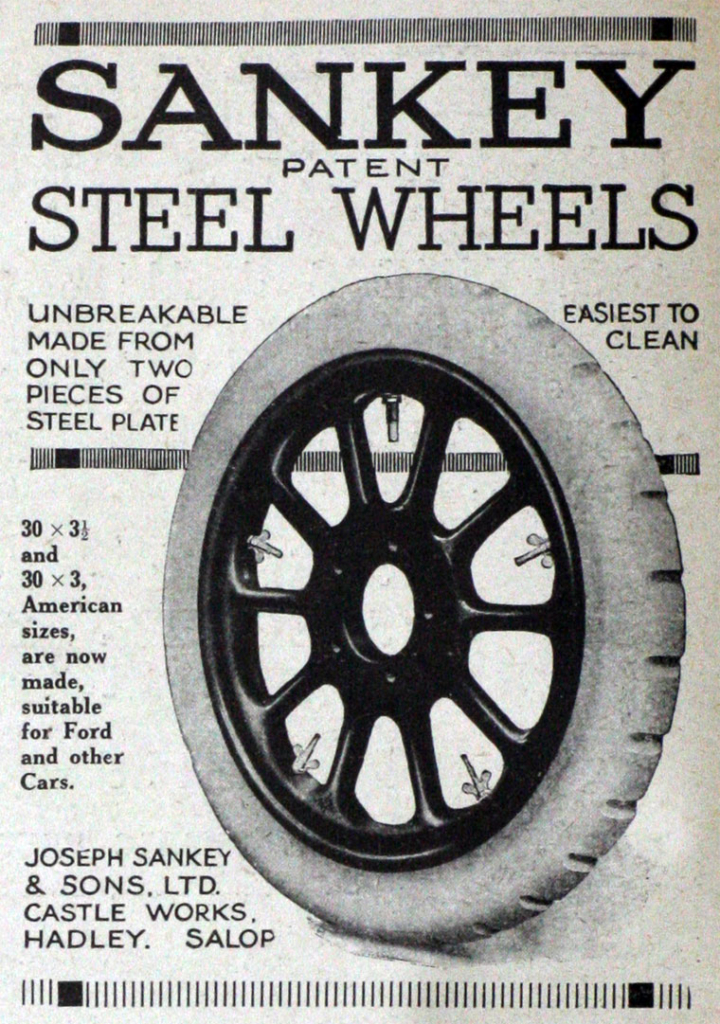

As early as 1908, the British company Sankey developed and patented the first pressed and welded detachable metal wheel, though still fashioned in the artillery style. Marketed as the cleverly-named “All Steel Wheel,” it went into production in 1910 as an option by some carmakers. By the mid-1920s, full-diameter disc-style steel wheels became available on regular production vehicles, including the venerable Model T.

It wasn’t until 1934 that we got the modern drop-center, pressed steel wheel, a.k.a., “the steelie” that we know and love today. This design was inherently strong because of the structure created by stamping its center. It was lighter, too, because unlike previous designs it only required a single piece of steel to form the dish. Further weight reduction could be achieved by removing extraneous material in the form of holes, slots, or “spoke” openings which also gave the wheels unique style. The instant snap-on flair of decorative partial hub caps or full wheel covers dressed them up even further.

It wasn’t long after the steelie’s introduction before the old types of wheels fell out of favor completely. Pierce Arrow may have been the last carmaker to offer wooden wheels in 1937. Wire wheels, the other old school favorite, would live on for several more decades, though mostly on English and Italian sports cars and tacky ‘80s neo-classic atrocities.

The first cast magnesium wheels emerged about the same time as their pressed steel counterparts but were expensive and quite rare until the 1950s. Because of their lightness, especially when forged, they primarily saw service on race cars. Companies like Halibrand and Campagnolo popularized “mag” wheels in every corner of the racing world.

The particular magnesium alloy used in wheels was prone to corrosion, however, and by the 1960s aluminum started replacing magnesium as the light alloy of choice. Aluminum is more abundant and easier to form than magnesium (which is highly flammable in both powdered and molten form), and by the 1970s cast aluminum wheels were showing up as options even on economy cars like Volkswagens and Datsuns.

Alloy wheels didn’t spell the immediate end for the trusty drop-center steelie which would, in fact, remain the dominant design for more than half a century. However, as the 1980s were drawing to a close, if anyone was truly excited about steel wheels, they were probably talking about the new Rolling Stones album (and I’m not the only one with mixed emotions about this one). By the time Mick and the boys released “A Bigger Bang” (it was 2005, in case that album doesn’t register with you) alloy wheels were more popular than the old stand-by, which now seemed as uncool as, I don’t know, wooden spokes.

But as alloys began to fill the fenders of every dealer’s inventory, steelies were plotting their comeback. They started gaining an underground following in certain automotive circles.

Among enthusiasts of high-performance European vehicles, it may have started with the rising popularity of high-performance snow tires. Owning a dedicated set of winter rubber meant you could safely powerslide your M3 with confidence all year round. Simple, affordable black steel wheels popped up as the perfect recommended pairing for Blizzaks with all our favorite online tire sellers. In a few short years, bare black steelies emerges as a badge of honor for tire snobs.

More universally, the 500-hp “sleeper” in tuner car culture lends itself perfectly to being paired with steel wheels. What better way to embarrass some fool in a muscle car than to blow his doors off with a Plain Jane Subaru hatchback on steel wheels? Never mind it’s packing full Cobb tuning under the hood and those steelies are wrapped in sticky ultra-high-performance rubber. We just followed the cops’ lead on this one, with their slick-top Police Interceptor Crown Vics wearing service-grade stamped steel rollers.

When it comes to off-roaders, they’ve known all along the value of steel wheels on rough terrain. Sure, those bead-lock alloys look badass and will keep your sidewall seated when you’re aired down for slick rock conditions. But when you’re in the backwoods of Vermont and find a vein of the local granite the hard way, chances are that alloy wheel’s going to suffer irreparable damage. Steel might bend more easily, but it doesn’t often crack. Thanks to steel’s malleability, a damaged rim can often be field repaired with a sledgehammer or a Hi-Lift jack, getting you safely out of the woods.

It’s no wonder a whole new crop of rough and tumble off-roaders is coming factory-equipped with good-looking steel wheels as standard. From Ford’s new entry level Maverick pickup to its more serious Bronco (including both full-size and Sport models), steel is in fashion. Even luxury off-roaders like Land Rover’s new Defender can be seen wearing steel (finished in white to match the roof, naturally).

So it seems the steel wheel has come full circle, pun fully intended. What were once innovative and new became ubiquitous and functional before falling out of the limelight to be adopted by the cool kids. Today they possess a retro-hipster/rockabilly timelessness. With the right context and intent, they can be dressed up or down for desired effect.

Converse Chuck Taylors, indeed.

The articles and other content contained on this site may contain links to third party websites. By clicking them, you consent to Dorman’s Website Use Agreement.

Participation in this forum is subject to Dorman’s Website Terms & Conditions. Please read our Comment Policy before commenting.